Welded mesh wire is a versatile and robust type of fencing material made from intersecting wires that are welded together at each junction. This creates a grid-like structure that is used in a variety of applications, including construction, security, and industrial settings. It is known for its durability, strength, and ease of installation.

Types of Welded Mesh Wire

- Standard Welded Mesh: Features a regular grid pattern with uniform spacing between wires, commonly used for fencing and reinforcement.

- Heavy-Duty Welded Mesh: Made with thicker wires for increased strength and durability, suitable for high-load applications and heavy-duty use.

- Custom Welded Mesh: Can be manufactured to specific dimensions, wire gauges, and grid patterns to meet unique project requirements.

Key Features

- Durability: Constructed from high-quality steel, welded mesh wire is resistant to deformation and rust, providing long-lasting performance.

- Strength: The welding process creates a strong bond at each intersection, ensuring the mesh can withstand significant stress and pressure.

- Versatility: Available in various sizes and configurations, it can be used for fencing, reinforcement, and other structural applications.

- Ease of Installation: The mesh panels can be quickly installed using standard tools and methods, saving time and labor.

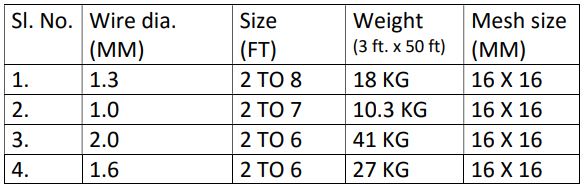

Available Sizes

Applications

- Fencing: Used for residential, commercial, and industrial fencing to secure properties and control access.

- Reinforcement: Commonly used in concrete construction to reinforce and strengthen structures such as foundations, walls, and floors.

- Animal Enclosures: Provides secure and durable enclosures for livestock, pets, and wildlife.

- Industrial Uses: Employed in various industrial applications, including machine guards, storage cages, and safety barriers.

Installation

- Preparation: Ensure the area where the mesh will be installed is clean and level.

- Mounting: Panels can be attached to posts using clips, ties, or welding, depending on the application and requirements.

- Finishing: Edges and joints should be properly secured and finished to prevent injury and ensure longevity.

Maintenance

- Inspection: Regularly check the mesh for signs of wear, rust, or damage, and perform necessary repairs or replacements.

- Cleaning: Keep the mesh clean and free of debris to maintain its appearance and functionality.

Benefits of Welded Mesh Wire

- High Strength-to-Weight Ratio: Provides strong reinforcement while being relatively lightweight, making it easy to handle and install.

- Aesthetic Appeal: Offers a neat and uniform appearance, enhancing the visual appeal of fencing and construction projects.

- Cost-Effective: Provides excellent performance at a competitive price, making it a cost-effective choice for many applications.

Why Choose Welded Mesh Wire?

Welded mesh wire is an excellent choice for a wide range of applications due to its strength, versatility, and durability. Whether you’re looking for reliable fencing, effective reinforcement, or industrial solutions, welded mesh wire offers a robust and efficient solution. Understanding its features and applications helps you select the right type for your specific needs and ensure optimal performance.